|

Accueil

>

Services

>

Avantor Services

>

Resources

>

Success Stories

>

Creating the Ideal University Stockroom

Creating the Ideal University StockroomChallengeReducing costs can be a tricky puzzle for any organization, but for this multi-campus university faced with impending state-wide budget cuts to higher education, it was a dire necessity. Scarce resources limited the university’s ability to identify their most probable opportunities for waste reduction, especially amid a complex mix of political, financial, and operational pressures. Between the interests and influences of university and department leaders and the financial pressure from principal investigators to reconcile stockroom budgets, in the end the most important objective was to meet the needs of researchers and to ensure that all the data flowed smoothly among the various university departments. University leaders turned to VWR’s Business Process Consulting team to ask: how do we construct the ideal campus-wide stockroom model, one that would cut costs while enhancing the services that our researchers care about the most? SolutionAn Avantor Services Lean Six Sigma-trained Process Consultant began with a project charter detailing expected project results based on a matrix of goals and objectives for each stakeholder group. Together with project management tools, this data ensured the final results would meet the needs and timeline of those most affected. Extensive surveying, onsite interviews, and transactional data captured the political landscape, voice of the customer, and the process data at the center of the detailed financial models. Sources of Waste in the University's Stockrooms

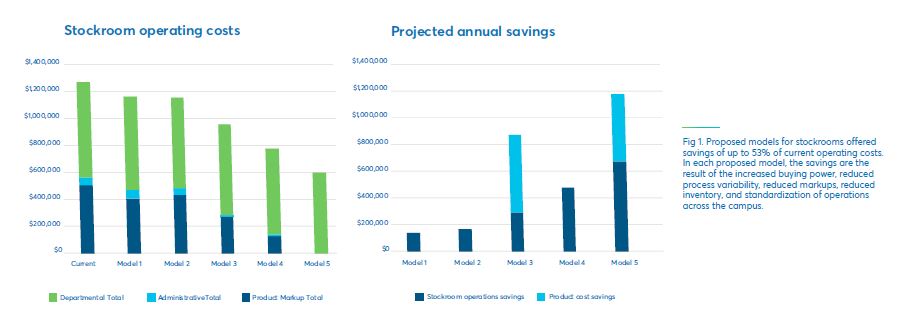

When the project began, the university had three distinct stockroom models in place: two of the models were managed by university staff and funded exclusively by a university price markup ranging between 14 and 44%; the third was managed by a vendor, funded at less than 1% price markup. Service levels, management structures, and end-user sentiment differed across campus, and some researchers were very price conscious while others cared most about customer service. ResultIn less than 30 days, our consultant distilled this complex landscape into five viable stockroom models, each tailored to the needs of the stakeholders, with proposed savings as high as $1.1 million. The proposals included:

ChallengeA large university had to cut the cost of maintaining and operating their stockrooms while balancing the needs and goals of many departments and university leaders. SolutionThe Avantor Services consultant used Lean Six Sigma methodology to capture the complex landscape of the university and its stockroom needs. ResultThe consultant presented five different models for stockroom management, with proposed savings of up to $1.1 million. Need Help?Are your scientific resources being wasted on non-research activities? Avantor Services has the skills, knowledge, and experience to support productivity improvement at your organization. |

|

Traitement de votre demande ... |