Masterflex® MasterSense™ Gear & Piston Process PumpsFeatures that make your process effortless

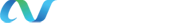

1

Perfect for sanitary environments —

2

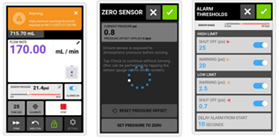

Sensors integrated into the flow path monitor fluid pressure and alert before there is a potential for process failure.

3

Intuitive digital touchscreen with optimized menu navigation to store and recall standard protocols ensuring continuity-

4

Over-the-air firmware updates ensure optimization of your pump system without moving the system

5

Superior mechanical design supports higher flow ranges, pressures and torque capability for greater repeatability and pumping higher viscosity fluids.

6

Gear Pumps are the optimal choice for pumping clean fluids in higher pressure, pulseless flow applications.

7

Piston Pumps offer high repeatability for critical dispense applications where change-out and lot-to-lot contamination is not critical.

Continous Mode*

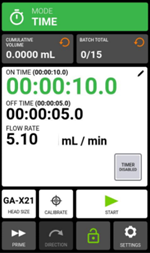

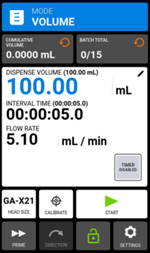

Time Mode

Volume Dispense

Pressure

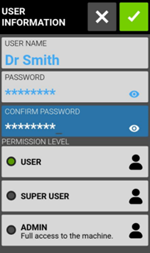

User Access

Program Save & Recall

Network Detection

Remote Mode*

Head Calibration* Integrated sensor monitors your media so you don’t have toSeamless monitoring, avoid risk and save money

Advanced Connectivity and Control OptionsMonitor from anywhere

Flexible Connectivity

Gear pump complete system componentsTo create a complete pump system, a drive and pump head are needed. Complete systems are available for common configurations (see table below), or choose the pump drive and select from a variety of Suction shoe mount A or B, or cavity style head pump head options available.

Learn more - See Gear pump performance and technical spec sheet

Gear pump heads

Piston pump complete system componentsTo create a complete pump system, a drive and pump head are needed. Complete systems are available for common configurations (see table below), or choose the pump drive and select from a variety of Q-series or Rh-Series Piston pump heads. An adapter required for low-flow RH models.

Piston pump heads |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Traitement de votre demande ... |